Key Takeaways

- Routine pipeline cleaning eliminates blockages, reduces operational costs, and maintains safe flow rates.

- Emerging tools such as smart pigging increase inspection accuracy and cleaning efficiency.

- Compliance with safety practices and environmental standards remains essential during all cleaning operations.

Table of Contents

- Importance of Regular Pipeline Cleaning

- Common Pipeline Cleaning Methods

- Advanced Technologies in Pipeline Cleaning

- Safety Protocols During Cleaning Operations

- Environmental Considerations

- Regulatory Compliance

- Training and Certification

- Conclusion

For industries such as oil and gas, chemical manufacturing, and water utilities, ensuring the longevity and efficiency of their pipeline infrastructure is essential. Regular, effective cleaning not only prevents operational disruptions but also reduces long-term costs and environmental risks. Modern solutions, such as intelligent pipeline pigs, have revolutionized how technicians approach pipeline cleaning, improving precision and safety.

By staying up to date on the latest methods and technologies, organizations can minimize downtime, prevent hazardous leaks, and improve the overall reliability of their pipeline systems. Reinforcing best practices in cleaning is also fundamental to meeting industry standards, ensuring worker safety, and advancing environmental stewardship.

As operations become more automated and data-driven, it is increasingly important to select cleaning approaches tailored to the specific challenges of each system—from preventing biofilm buildup in water lines to managing corrosion in oil and gas pipelines. A robust cleaning strategy not only safeguards product quality but also ensures regulatory compliance and community trust.

Industry leaders continue to invest in staff training, innovative equipment, and strategic partnerships to adopt the latest advancements and reduce risks.

Importance of Regular Pipeline Cleaning

Preventing the buildup of debris, rust, and biofilm through regular pipeline cleaning is a critical factor in keeping industrial systems operating smoothly. Over time, even small amounts of scale or residue can impede flow, triggering pressure drops and increasing the energy needed for pumping. According to industry studies, failure to maintain clean pipelines can cause operational efficiency losses of 5–10%, directly impacting company profitability and safety.

Frequent cleaning also plays a crucial role in identifying early signs of corrosion or leaking joints before they escalate into costly repair issues. In sectors such as water treatment, where public health is at risk, maintaining clean pipelines is not only an economic consideration but also a key regulatory requirement.Common Pipeline Cleaning Methods

Various cleaning methods are available, each best suited for particular contaminants and pipeline configurations:

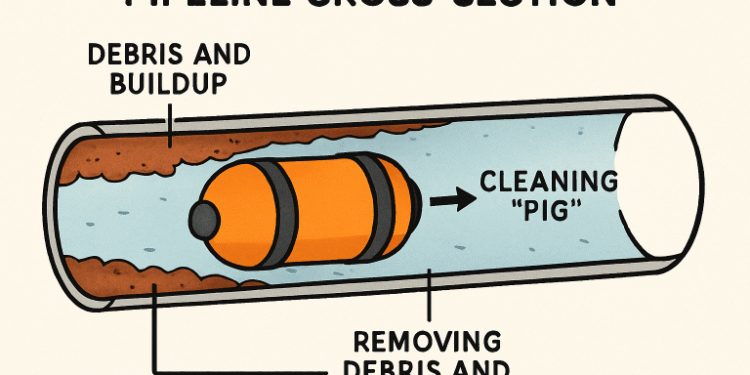

- Mechanical Pigging: Mechanical pigs—cylindrical devices inserted into the pipeline—physically scrape and push debris along the line to a collection point.

- Chemical Cleaning: Involves introducing chemical agents that dissolve mineral scale or other stubborn deposits, which are then flushed away with the liquid product or water.

- High-Pressure Jetting: Water jets at extremely high pressures remove internal buildup, biofilm, or mineral scaling, making this method ideal for water and sewer lines.

- Ice Pigging: Uses a slurry of ice to scour pipes, then safely melts and carries away soft blockages, minimizing chemical use and allowing easy cleanup.

A tailored combination of these techniques ensures optimal outcomes for diverse pipeline materials and contents.

Advanced Technologies in Pipeline Cleaning

The adoption of new technology has redefined pipeline cleaning and inspection:

- Smart Pigging: By embedding sensors within pipeline pigs, operators can gather real-time data on pipe wall thickness, identify corrosion, and pinpoint structural weaknesses—enabling predictive maintenance and targeted cleaning strategies.

- Robotics and Automation: Self-navigating robots conduct inspections and perform cleaning tasks, especially in hazardous or inaccessible areas, reducing the need for personnel entry and exposure to risk.

- Machine Learning Applications: Artificial intelligence systems analyze collected data to forecast pipeline degradation and suggest optimal cleaning intervals, reducing unnecessary maintenance and lowering costs.

Safety Protocols During Cleaning Operations

Worker safety and risk management must underpin every cleaning procedure. Standard protocols include:

- Conducting comprehensive risk assessments before beginning any cleaning process.

- Issuing and monitoring the use of personal protective equipment (PPE), including respirators, gloves, and eye protection.

- Developing and rehearsing emergency response plans for leaks, spills, or equipment failures.

- Ensuring only certified and trained personnel undertake operations involving hazardous materials or pressurized equipment.

Environmental Considerations

Responsible pipeline cleaning mandates a strong commitment to minimizing environmental impact. This includes:

- Selecting biodegradable or non-toxic cleaning agents to limit pollution.

- Capturing and disposing of waste and runoff material in accordance with environmental regulations.

- Implementing spill-prevention controls and monitoring systems to detect and address leaks rapidly.

Adhering to environmental best practices protects not only ecosystems but also a company’s reputation and legal standing.

Regulatory Compliance

Staying current with evolving industry regulations is non-negotiable. Key compliance best practices include:

- Reviewing and updating cleaning protocols in response to regulatory changes at the local, national, and global levels.

- Maintaining thorough records of each cleaning event for both internal audits and third-party inspections.

- Engaging proactively with regulatory agencies to clarify expectations and standards as new technologies are implemented.

Non-compliance can result in significant fines, work stoppages, and reputational harm, making continuous education a critical organizational function.

Training and Certification

Only qualified technicians should oversee pipeline cleaning operations. Effective programs provide:

- Skill-building in both technical cleaning procedures and safety management.

- Opportunities for staff to earn and renew credentials, including confined space entry and hazardous materials handling.

- Up-to-date instruction on the proper use of emerging technology and best environmental practices.

Conclusion

Committing to best practices for pipeline cleaning ensures dependable operation, protects worker safety, and safeguards the environment. Integrating advanced tools such as intelligent pipeline pigs and robust automation, while staying attentive to regulatory developments and training needs, enables companies to achieve higher standards of performance and sustainability. By prioritizing these strategies, organizations can future-proof their essential infrastructure and maintain a reputation for operational excellence.