Do you often wonder how much steel is required for a project? Many construction professionals, architects, and engineers face this question every day. With the complexity of design standards constantly increasing, it’s essential to have accurate information about steel materials when building a structure or installing components.

Steel is one of the most commonly used materials in construction, especially for larger and more complex projects. Not only is it durable and cost-effective, but it’s also extremely versatile, making it a popular choice for professional builders and DIYers alike. But before you begin anything, you need to know how much steel your project requires. To ensure you get enough without wasting time or money on unnecessary materials figuring out exactly how much steel you need might seem tricky at first but with a few calculations and some knowledge of basic building guidelines, precise measurements can be attained every time!

In this blog post, we’ll break down the specifics of deciding on an appropriate amount of steel for any project from understanding what types are available and identifying load-bearing requirements to creating your budget and considering overall safety concerns. Keep reading to get everything you need to know!

Types of Steel and Their Uses

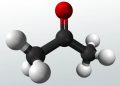

Steel is an alloy made with iron, carbon, and other elements that can be combined to create a variety of grades. Depending on its composition, steel can be used in many different applications. Here are some common types of steel and their uses:

1. High Carbon Steel:

High carbon steel is one of the most widely used materials for tools and equipment due to its hard-wearing properties. It is commonly used in cutting tools, springs, knives, hammers and axes as well as construction materials such as bolts and nuts.

2. Low Carbon Steel:

Low carbon steel is highly formable when hot working but has less strength than high carbon steel. This type of steel is used in automotive components, appliances, pipes and tubes, structural shapes and other low-stress applications.

3. Tool Steel:

Tool steel is manufactured to be hard and durable for use in cutting tools such as drill bits and other metalworking instruments. The high carbon content of tool steel makes it exceptionally wear-resistant while also providing excellent heat resistance.

4. Stainless Steel:

Stainless steel is an alloy of iron that contains a minimum of 10% chromium and provides superior corrosion resistance compared to other types of steel. It is commonly used in a wide range of industries, including food production, construction, chemical processing, architecture and transport engineering.

5. Alloy Steel:

Alloy steels are made with combinations of different elements such as nickel or copper, which can produce steels with enhanced properties. Depending on their composition, alloy steels can be used in a variety of applications including automotive parts, pipelines and construction projects.

These are just some of the most common types of steel and their uses. There are many other alloys that have been developed to meet specific needs for strength, corrosion resistance or heat tolerance. No matter what your requirements may be, there is certainly a type of steel suitable for the job!

Calculating the Necessary Amount of Steel for a Project

When it comes to structural steel estimating services, steel is one of the most important materials. It provides strength and stability while also being relatively lightweight and cost-effective. In order to ensure that a project can be completed safely and effectively, it’s essential to know how much steel will be needed before starting any work. Here are some steps to help you calculate the necessary amount of steel for your project:

1. Analyze Your Project Requirements

Before you start calculating, it’s important to understand what requirements your project has. Consider factors such as size, shape, load-bearing capability, design complexity, and installation methods. This will help you narrow down the types of steel that are best suited for your project.

2. Determine the Type of Steel Needed

Once you have a better understanding of the requirements, it’s time to figure out which type of steel will work best for your project. This decision should be based on factors such as strength, corrosion resistance, and cost-effectiveness. Depending on your needs, there are several different types of steel that may work well – including mild steel, stainless steel, and galvanized steel.

3. Calculate the Volume or Weight Required

Now that you’ve determined the type of steel needed for your project, it’s time to calculate how much of it you’ll need. For most projects, this is done by calculating the volume or weight required for the project. This can be done using simple equations or online calculators. Once you have the amount of steel needed, you can then determine how many pieces and what sizes are necessary to complete your project.

4. Factor in Safety Measures

Finally, when calculating the amount of steel needed for a project it’s important to factor in safety measures. This includes adding extra steel for joints and supports that may be necessary based on design requirements or environmental factors such as wind or earthquakes. It also means considering additional steel reinforcements if a structure will be subjected to heavy loads or vibrations over time.

Determining the necessary amount of steel for a project can be an arduous task when trying to find the right balance between cost efficiency and safety. It is important to take into account the project’s varying needs, as well as other factors such as climate, seismic activity, wind speed, and fire resistance.

From there, you can better understand what kind of steel your project is going to require and how much of it will be necessary to achieve optimal results. Taking the time to research the right type and amount of steel that your project requires is essential to its success, it will need not just any steel but the right kind in order to meet your desired outcome. Heed these tips and have faith in your decisions so that you can rest assured knowing that you’ve made choices that keep both cost efficiency and safety in mind.